Test, Measurement and Calibration

Engineering Dynamics Provides a range of test services – all conducted using equipment and machines which are independently tested by NATA Accredited Test Facility / Facilities.

Static Load Testing

- Testing Of Rubber and Spring Isolators for Load and deflection capacity

- Testing of Materials and Composites for failure loading and safe load capacity

- Testing of Beams for load, deflection and determination of E (Youngs Modulus)

Dynamic Load Testing

- Testing of rubber and spring isolators to determine Dynamic Stiffness

- Testing of materials and Structural members for flexure and failure (rupture loads)

- Test of products for fatigue

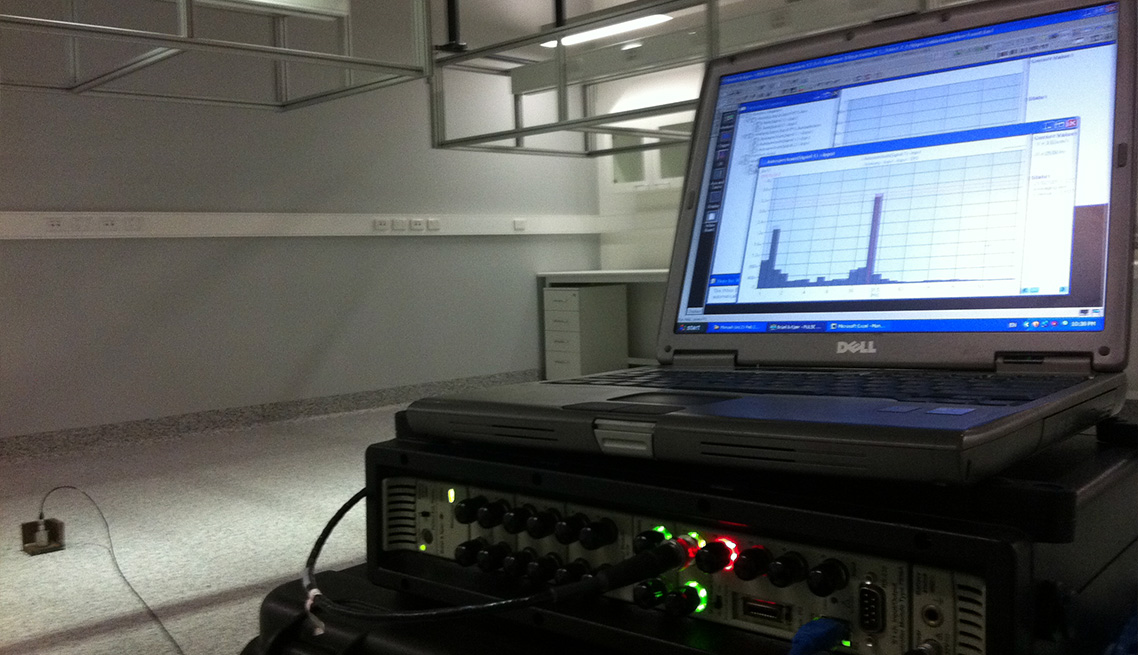

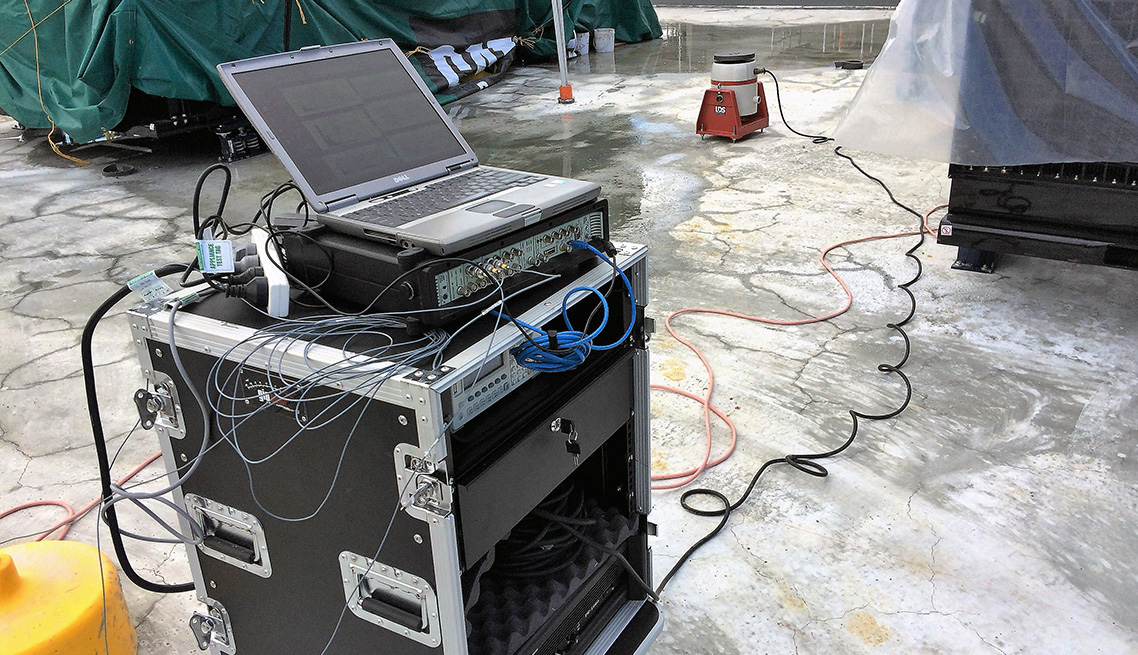

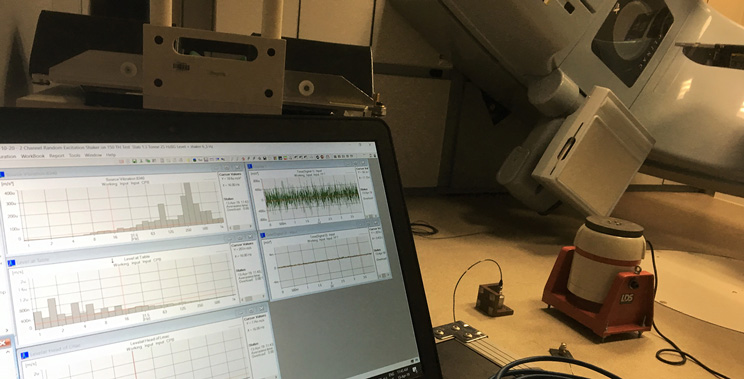

Shaker Testing

Engineering Dynamics has a range of electrodynamic shakers from 10N up to 2.2kN capacity along with hydraulic and pneumatic option machines for determining natural frequency, response factor, and in some cases fatigue.

These are used as the backbone of our vibration isolation range of products to ensure high performance in all aspects.

Some of these dynamic shakers can also be used onsite where required to validate structural design and provide confirmation of mode shapes, natural frequency and damping ratio along with vibration isolation performance.

Other Testing

- Modal Testing

- Absorption Coefficient Testing

- Sound Impact Isolation Testing

- Sound Power Measurement

- Sound Intensity Measurement

- Rubber Compound Testing

- Creep Tests

- Bridge Bearing Testing

- Vibration Testing

- Non-Contact Laser Vibrometry

- Natural Frequency Testing

- Damping Coefficient Testing

- Noise Measurement

- Dosimetry / OH&S Noise Assessment

- Sound Transmission Loss / Noise Reduction Testing